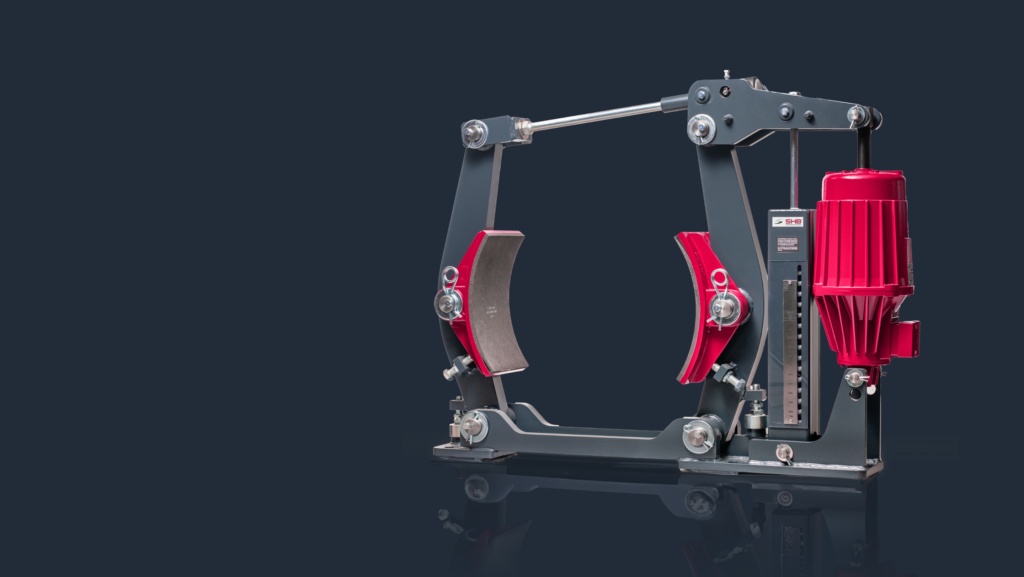

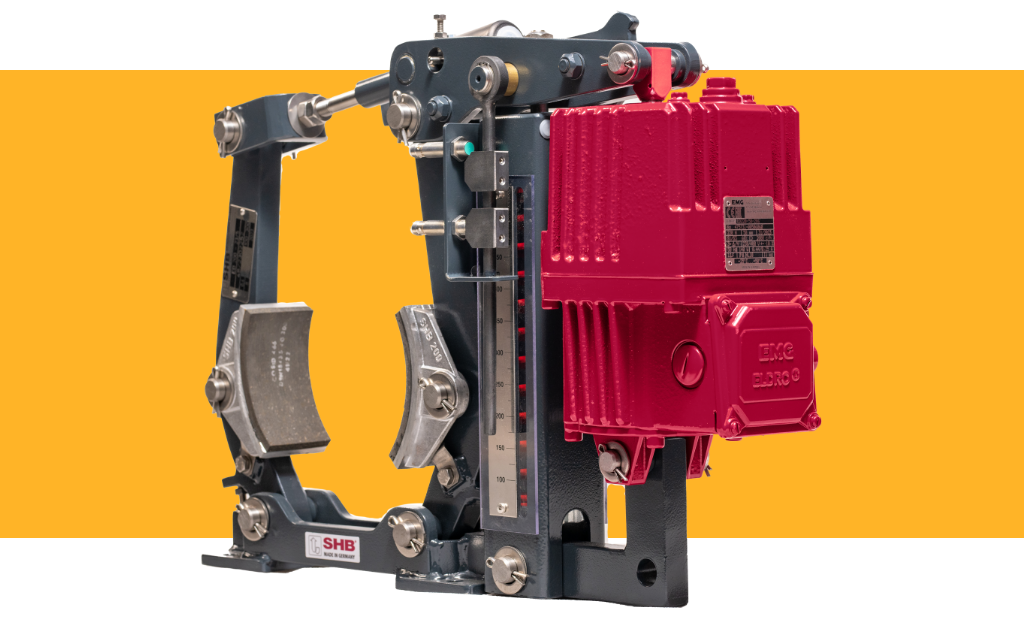

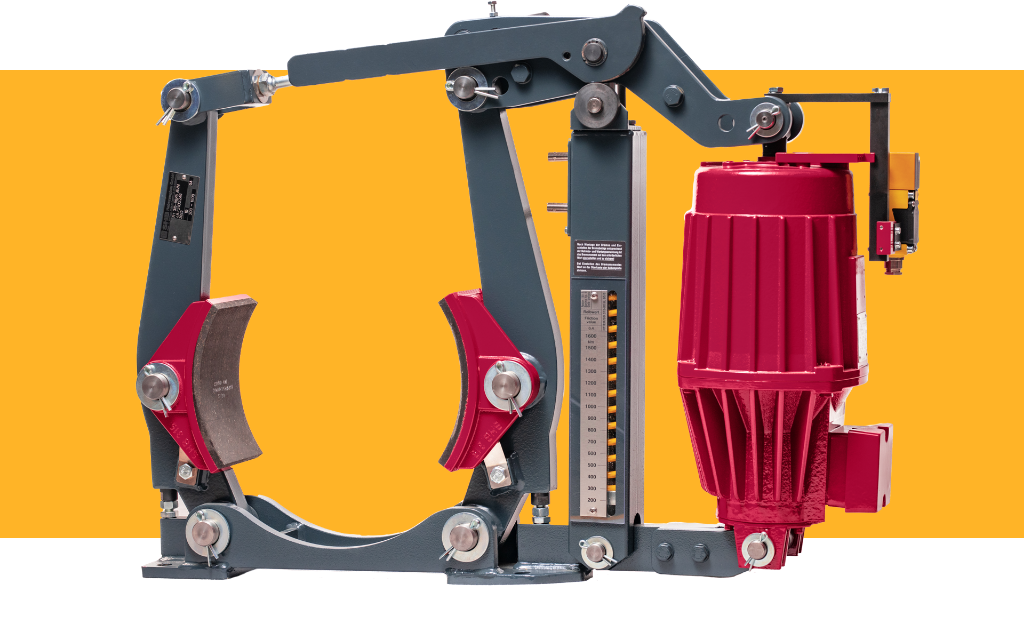

DRUM BRAKES

ACCORDING TO DIN 15435

ACCORDING TO DIN 15435

ACCORDING TO DIN 15435

SHB drum brakes, compliant with DIN 15435, use a cylindrical helical compression spring as the actuating element. They are equipped with electro-hydraulic lifting devices in accordance with DIN 15430 as standard, but are also compatible with devices from different manufacturers. SHB drum brakes operate according to the "fail-safe" principle as standard.

We offer drum brakes with synchronous release mechanism, adjustable fixed stop and lifting devices positioned above the brake drum. Our brakes are designed for brake drum diameters from 160 mm to 800 mm and achieve maximum braking torques of up to 20,000 Nm. Depending on the application, the maximum sliding speed is up to 40 m/s.

Your advantages

Power range

PRODUCT DATA SHEETS

Design features

The main dimensions of the STB series drum brakes comply with TGL 38302, thus ensuring interchangeability with the A1, A2 or B double shoe brake in accordance with TGL 38302 and TGL 20-363000 without changing the brake substructure and brake drum.

Advantages compared to series A and B